The IA1000 is a next-generation automated ADAS calibration, wheel alignment, and advanced diagnostics system. Its robotic one-step forward-facing target positioning and calibration significantly reduces manual setup time, streamlining the process for maximum efficiency. Compatible with both traditional physical LDW targets and 27" digital monitors, featuring automatic target display and self-adjusting screen brightness for optimal visibility.

High-definition optical cameras combined with laser-guided Blind Spot, ACC, and AVM pattern positioning enhances accuracy while minimizing human error. To further ensure precision, the IA1000 includes automated floor compensation, eliminating failed calibrations caused by uneven surfaces. Go beyond basic camber, caster, and toe with industry-leading advanced wheel alignment and measurement data.

Additionally, comprehensive pre- and post-scan reporting validates every calibration, documenting every detail for accuracy and transparency. From wheel alignment, LDW, and all-systems ADAS calibration packages, the IA1000 delivers a tailored solution to meet your specific needs.

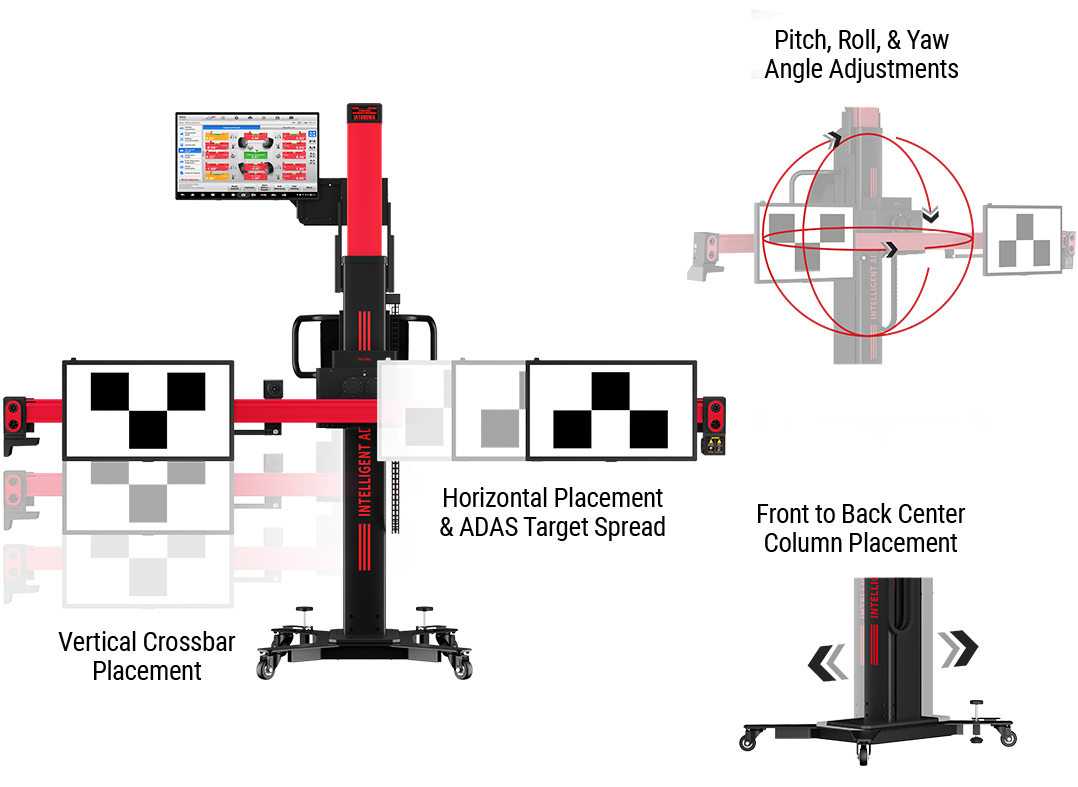

Position the system anywhere within the green Distance and Offset tolerances, hit "Next", and the IA1000 automates the rest of the setup.

Reduce setup time with robotic fine tune front-to-back, vertical and horizontal crossbar placement, pitch, roll, and yaw angles, and ADAS target spread—all with absolute precision.

Compatible with both traditional physical LDW targets and 27” digital monitors, featuring automatic target display and self-adjusting screen brightness for optimal visibility.

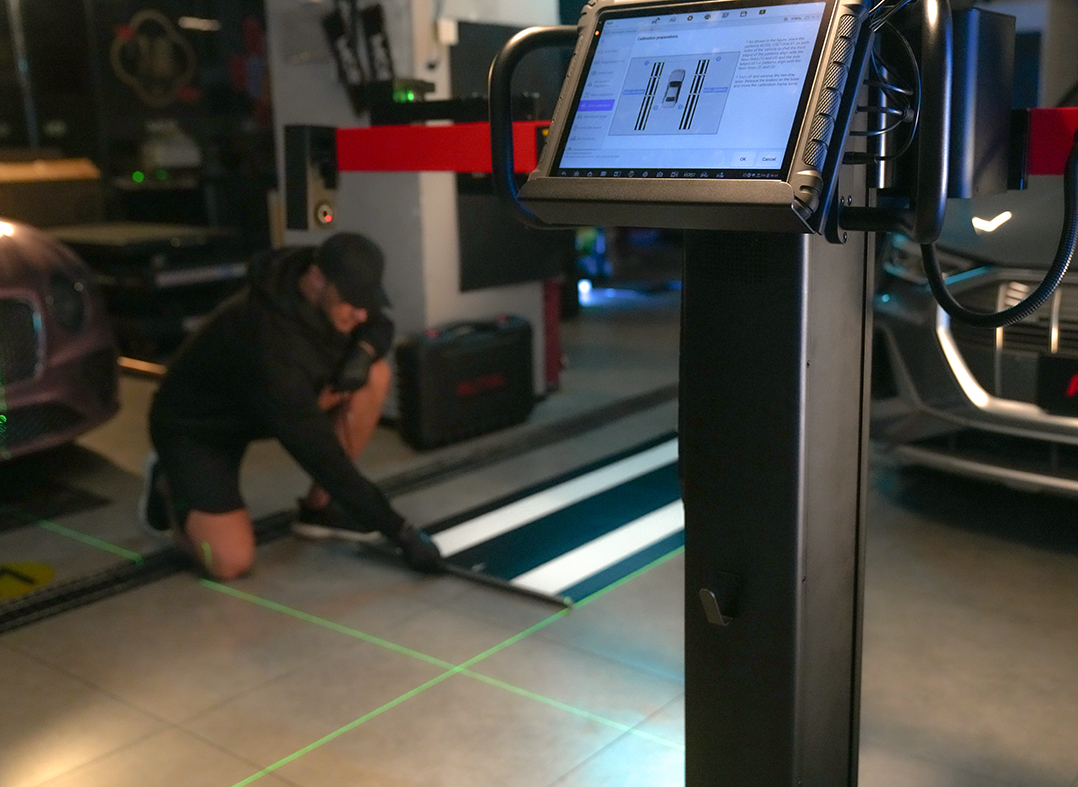

Validated target position reporting ensures comprehensive documentation for Pre/Post Scan reports and insurance compliance.

OEM-sourced software procedures guarantee every calibration meets manufacturer specifications.

Digital Go-No-Go confirmation verifies target placement, preventing errors before calibration begins.

Validated target position reporting ensures comprehensive documentation for Pre/Post Scan reports and insurance compliance.

OEM-sourced software procedures guarantee every calibration meets manufacturer specifications.

Digital Go-No-Go confirmation verifies target placement, preventing errors before calibration begins.

Current year alignment vehicle coverage, industry-leading alignment vehicle specs and coverage, with frequent updates.

Employing 6 HD position and tracking cameras, the IA1000 performs precise four-wheel alignments to 0.02 degrees of accuracy Step-by-step instructions guide the technician through the complete process with illustrated, color-coded alignment status, live readings, required tools.

Go beyond basic camber, caster, and toe with industry-leading advanced wheel alignment and measurement data.

MAX enables hands-free navigation of ADAS Calibration interface, initiate tasks and functions using your voice based on MaxiSys Ultra S2.

Effortlessly initiate a system scan, access maintenance tasks, or execute active tests, available on 16 key vehicle models.

Automated Unlevel Floor Compensation eliminates failed calibrations due to uneven surfaces.

Powered by the MaxiSYS Ultra S2 diagnostic scan tool with Topology 3.0 for deep system analysis.

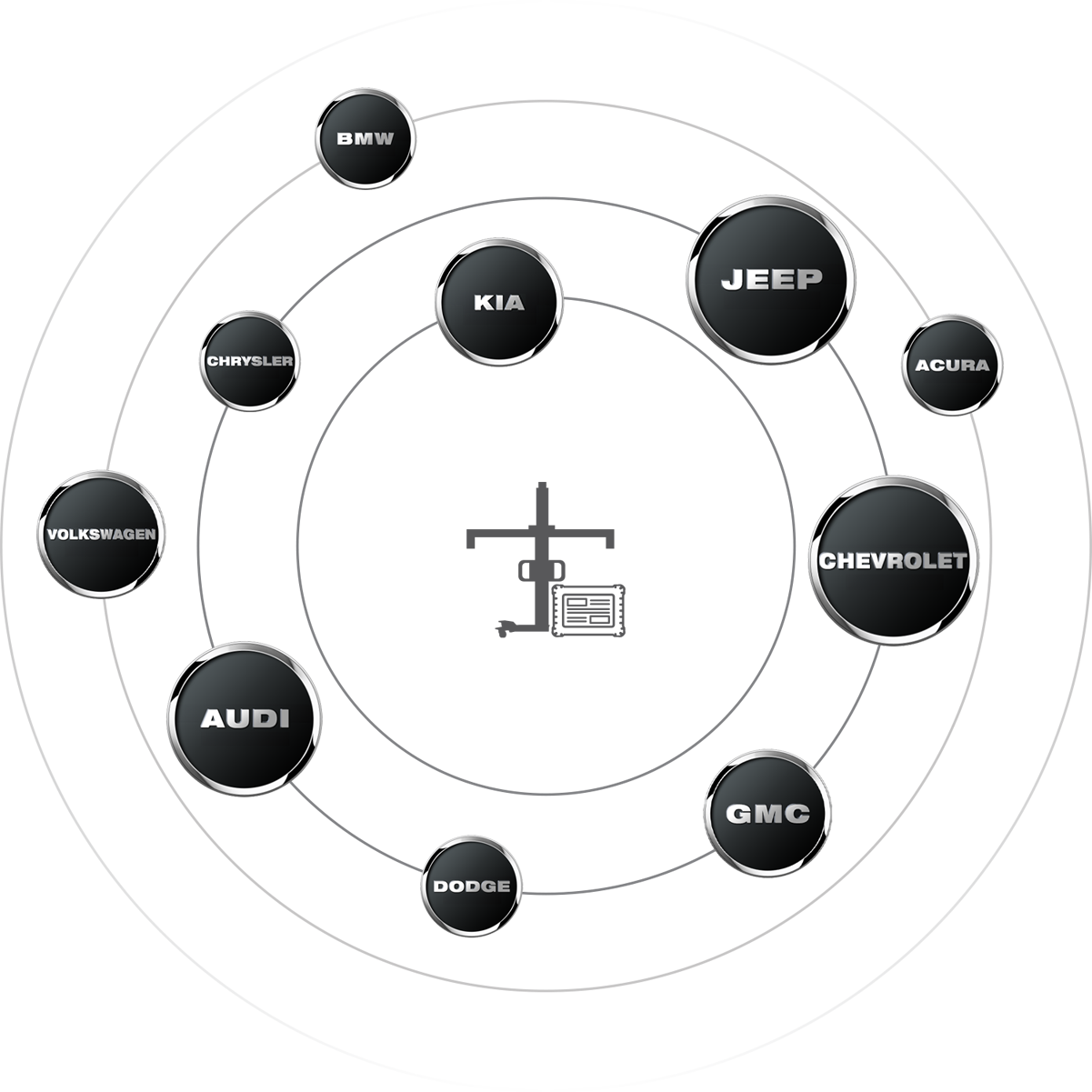

Industry-leading software and target coverage for U.S., Asian, and European vehicles.

Scalable system with multiple ADAS calibration and wheel alignment packages tailored to specific needs.

Easy-to-follow step by step instructions and graphical illustrations to ensure every calibration is performed safely and accurately to OE specs.

From pre-calibration vehicle and environment conditioning through positioning, calibration, and documentation, the Autel workflow ensures efficient and reimbursable calibrations every time.